GCMS Detector Preventative Maintenance Considerations: Daily MSD PFTBA Tuning and Evaluation

Your daily PFTBA tune is an invaluable tool to ensure optimum and reliable performance of your GCMS system. There’s more information and symptoms that a proper tuning can detect than you might realize.

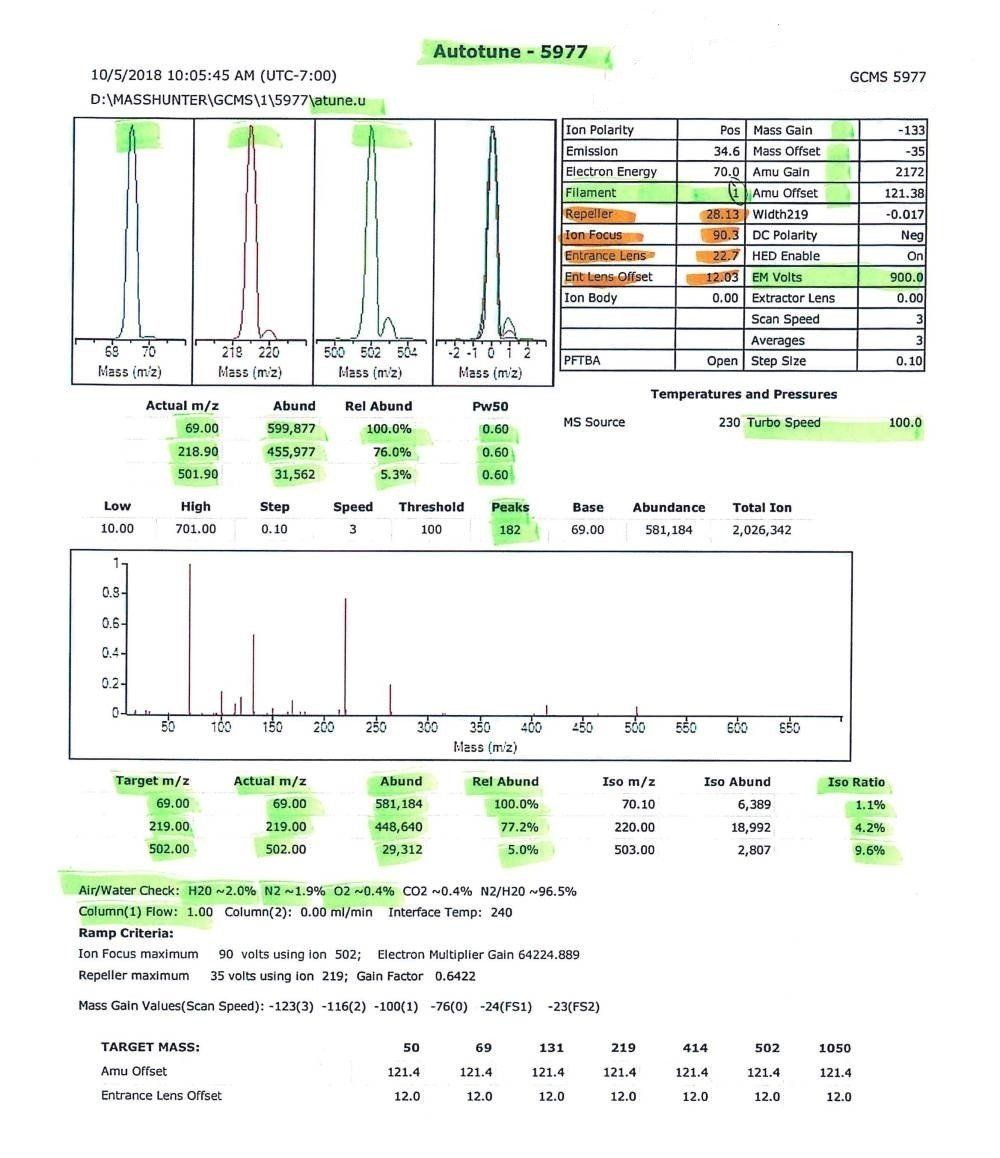

Autotuning the MSD should be done after maintenance, prior to initial calibration generation, or before running a sample sequence to ensure system performance and optimization. The tuning algorithm uses ratios of compound ions within a standardized tune solution (PFTBA) to adjust lens settings, electron multiplier voltages, quadrupole settings, and abundances to maximize performance of the MSD for your methodology. Autotuning will optimize the MSD with its present condition (newly cleaned or even if it’s been a while) as the tuning algorithm compensates for performance of aging or dirty components. It’s suggested to run the autotune, the same column flow rates and oven temperatures when using control charts. Autotuning is also useful after a source cleaning for future comparison of source aging and filament performance. Autotune on each filament to be objective about performance.

As a note, remember autotuning and generating a tune report are not the same things. The autotune uses a tuning algorithm to make a series of adjustments, while generating a tune report uses the final setpoints generated from the last saved autotune. This is preferred in some cases if you have a rather long (+24 hours) sequence or multiple shorter sequences but want the tune parameters to remain unchanged since the initial calibration is based on the first autotune results which are method and SOP specific. In general, you should autotune and recalibrate after maintenance is performed.

Additionally, the autotune can be saved and optimized for method specific performance. Standard tune, DFTPP tuning (for semi-volatiles), BFB tuning (volatiles), and target tuning are “canned” tune methods, created for just those purposes. Keep a record of these post source cleaning autotune reports in your instrument logbook maintenance section for later comparison. We suggest doing it for both filaments. Later, when comparing data, you’ll be glad you did.

The following are examples of such Autotunes and what to look for:

Autotune Reports from a clean 5977 MSD (Agilent) with Mass Hunter software

Tune Reports showing no changes from the same 5977 MSD (Agilent) with Mass Hunter software

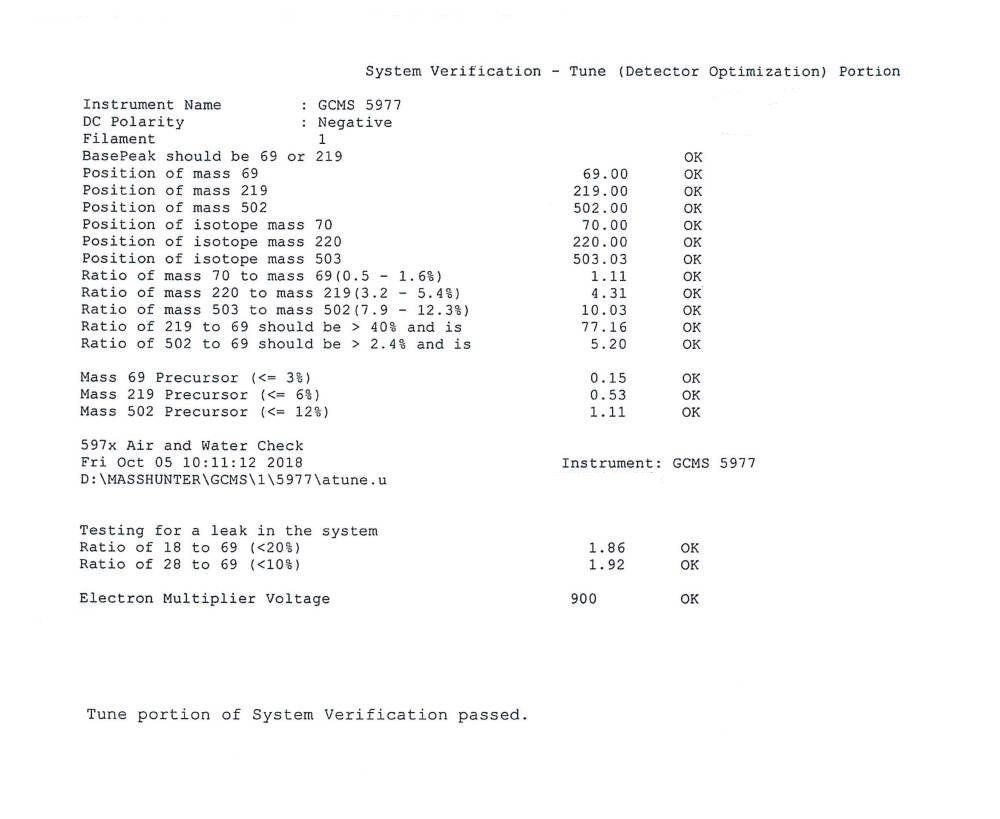

A Tune Evaluation is a separate internal MSD performance check using ion responses within the PFTBA solution against factory limits for that specific OEM’s MSD. This can also help in identifying required maintenance events. As before, use these post source cleaning Tune Evaluation reports for each filament in your instrument logbook maintenance section for later comparison.

The following are examples of such Tune Evaluations:

Tune Evaluation Reports from a clean 5977 MSD (Agilent) with Mass Hunter software

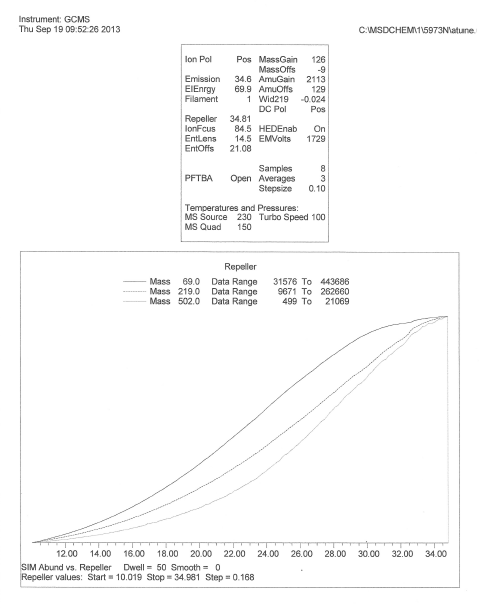

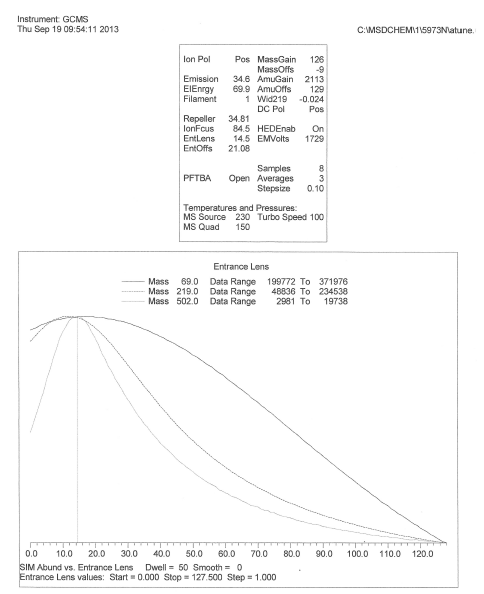

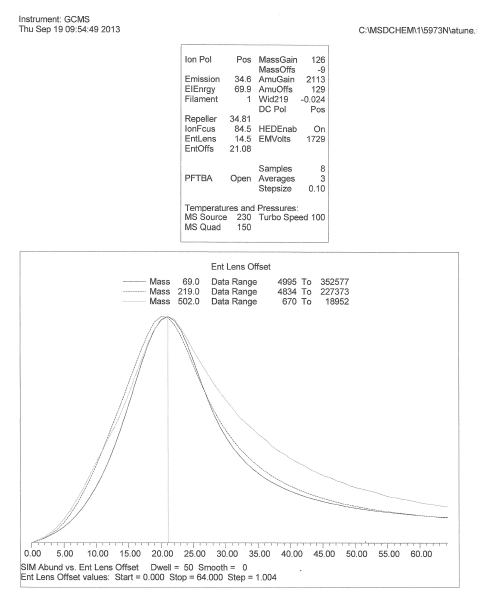

Parameter ramping of lenses is used within the autotune algorithm as an essential tool for evaluating the “cleanliness” of your MSD source and should be run on a scheduled basis. Autotuning is essential prior to initiating the parameter ramp evaluations. The three main ions being monitored (for example: 69, 219, 502) are graphically plotted for lens setting vs. abundance to determine the optimal lens setting for a particular mass and how that setting will affect the other two masses. This lens ramping is repeatedly used within the autotune algorithm along with varying the electron multiplier voltage and resulting responses. The shape of these graphically plotted masses will indicate a problem dirty component (i.e. repeller) or failing parts such as insulators which may need replacement. Use these post source cleaning parameter ramp reports for each filament in your instrument logbook maintenance section for later comparison.

By using these parameter ramps, autotunes, and tune evaluation reports you can determine your next troubleshooting step or strategy. Smooth flowing lines indicate good lenses; keep a record of these post source cleaning in your instrument logbook maintenance section for later comparison. Jagged or misshapen curves indicate interference (dirty or faulty lens, faulty wiring connection, or associated lens insulators are cracked).

The following are examples of such Parameter Ramps and issues that they may indicate:

Parameter ramps from a clean 5977 MSD (Agilent) with Mass Hunter software

Subscribe To Our Newsletter

We will get back to you as soon as possible.

Please try again later.